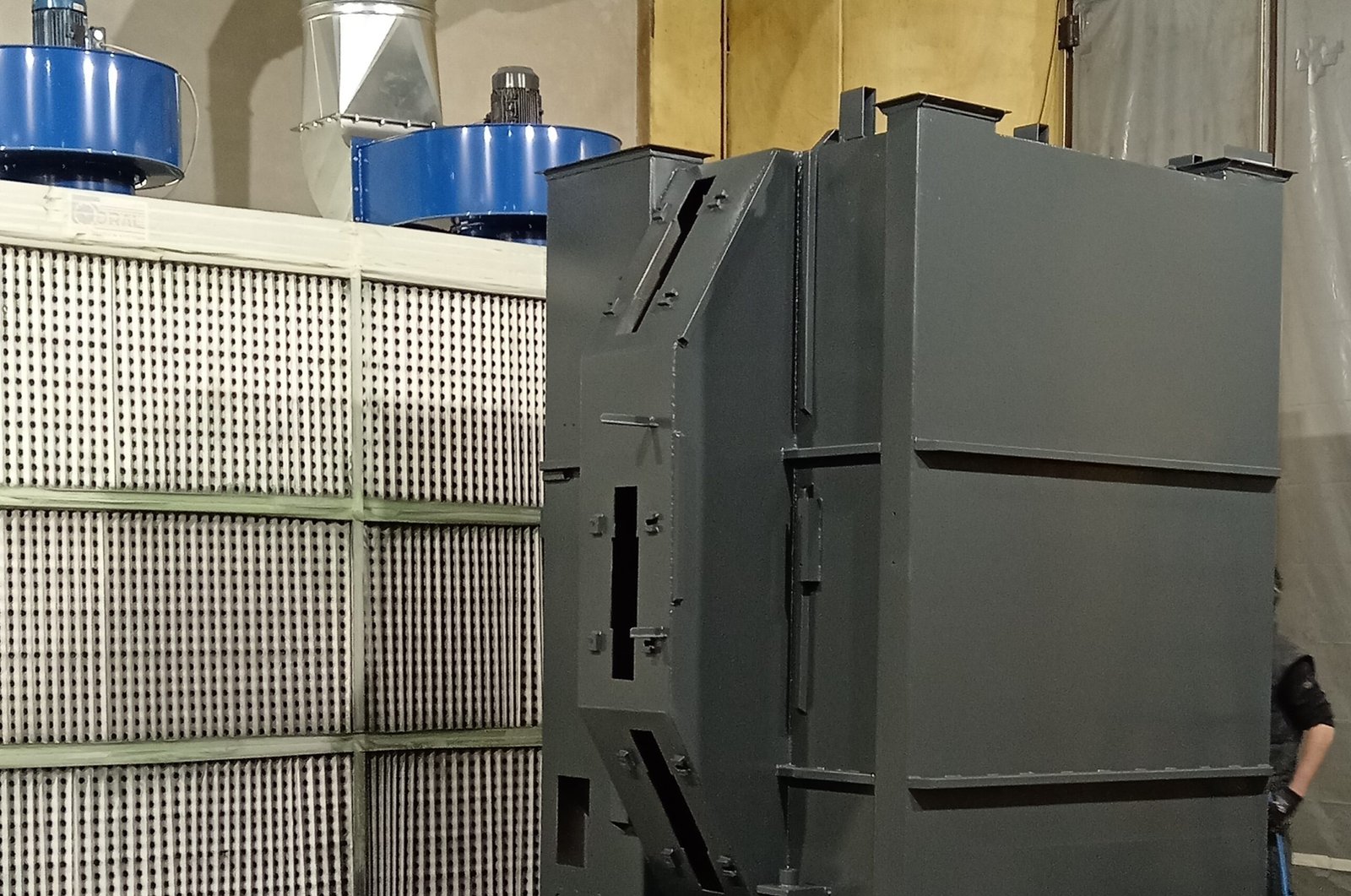

Powder coating for a uniform and highly durable finish

High-Quality Protection and Finishing

M.P. Carpenterie Srl offers a professional painting service for metal components, ensuring protection, durability, and impeccable aesthetics. Thanks to the use of advanced technologies and high-quality materials, we provide finishes that are resistant to weather, wear, and corrosion.

- Owner, MP Carpenterie

Painting Applications

🔹 Metal structures for industry and construction

🔹 Components for machinery and industrial plants

🔹 Bases, frames, and custom metalwork

🔹 Elements for the automotive, aerospace, and design sectors